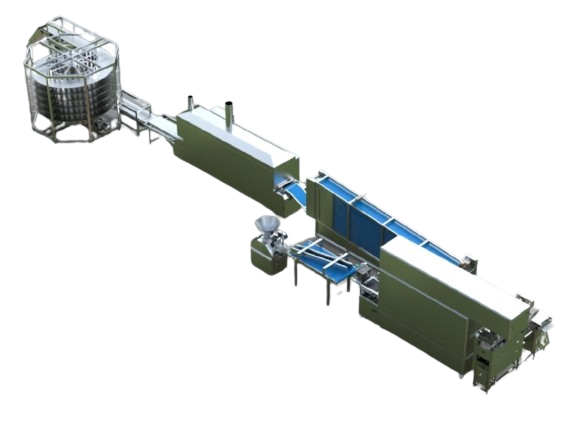

Pita production line

Our Pita Production Line is designed for optimal efficiency and flexibility, catering to bakeries of all sizes with diverse production capacities. It integrates advanced technology at every stage—from dough preparation to shaping, baking, and cooling—ensuring a streamlined process that delivers consistent, high-quality pita bread. This state-of-the-art system is crafted to help bakeries expand their product range while maintaining superior standards. With user-friendly controls, minimal maintenance requirements, and exceptional precision, it is the ideal solution for businesses focused on maximizing output and delivering authentic, premium pita bread.

Unmatched Efficiency in Pita Bread Production

As bakery technology advances, the Ultimate Pita Production Line sets a new standard for efficiency and innovation. This fully automated system revolutionizes pita bread production, offering a robust, comprehensive solution for high-demand bakeries. Designed to consistently deliver superior quality and precision, this line is more than just a machine—it’s a high-performance system built to transform your bakery’s productivity and output.

Tailored for Maximum Flexibility and Scalability

Recognizing that no two bakeries are the same, the Ultimate Pita Production Line is fully customizable to meet the unique needs of each operation. With options ranging from 2 to 8 rows or fully bespoke configurations, it seamlessly adapts to various production capacities and floor layouts. Whether you operate a small artisan bakery or a large-scale production facility, this line’s flexibility and precision engineering ensure optimal performance, enabling you to enhance output, streamline operations, and maintain impeccable product quality.

- Technical Specifiactions

- Benefits

- Options

▸ Capacity & Customization: Fully customizable to meet the exact needs of any bakery size, from small artisanal setups to large industrial operations. Our system is designed for maximum space efficiency, allowing for custom layouts that optimize your production environment.

▸ Premium Food-Grade Materials: Crafted from the highest-quality, food-safe materials, ensuring product purity and adherence to stringent safety standards throughout the production process.

▸ Cutting-Edge Pneumatic Systems: Engineered for superior performance, reliability, and smooth operation, guaranteeing consistent output even during high-volume production runs.

▸ Hygienic Anti-Bacterial Conveyor Belts: Featuring innovative, easy-to-clean, anti-bacterial belts to ensure a sanitary production process, drastically reducing the risk of contamination.

▸ Precision Speed Control: Equipped with advanced adjustable speed control technology, allowing seamless adaptation to varying production rates, ensuring consistent quality no matter the output demand.

▸ Advanced Electronics & Automation: High-grade electronic controls provide precision management and oversight, optimizing efficiency, consistency, and product uniformity while reducing energy consumption.

▸ Unrivaled Versatility: Engineered to produce a wide range of pita bread varieties, from traditional flatbreads to custom pita styles, giving your bakery the flexibility to cater to diverse customer demands.

▸ Superior Efficiency & Consistency: Our fully automated pita production line dramatically increases output while maintaining impeccable quality. By minimizing manual labor and human error, it ensures uniform size, shape, and texture with every batch, improving both productivity and product consistency.

▸ Cutting-Edge Automation: Advanced automation technologies streamline every stage of production—from dough preparation to baking and cooling—reducing operational costs and enhancing production speed while maintaining the highest hygiene and quality standards.

▸ All-in-One Solution: This comprehensive production system delivers end-to-end support, seamlessly integrating all stages of pita production for a smoother, faster, and more efficient operation. It ensures top-tier performance from dough mixing to final product cooling, giving your bakery a complete solution.

▸ Flexible Row Configuration: Choose from a wide range of configurations, including 2 to 8 rows or fully customized setups. This flexibility empowers your bakery to scale production efficiently, adapting to current needs while being ready for future growth, ensuring both adaptability and long-term success.

▸ Tailored Customization: Our solutions are designed to fit your specific production goals, whether you need unique layouts, specialized features, or custom production capacity. We offer tailor-made systems that align with your operational requirements.

▸ Collaborative Design Process: We take a consultative approach, working closely with you to fully understand your bakery’s unique challenges and aspirations. Our team designs solutions that maximize efficiency, boost output, and deliver superior results, ensuring your production line is optimized for success.

Discover Cutting-Edge Bread Production Equipments

Explore our advanced equipment designed for precision and high efficiency in bakery production.